Total control over your production

Integrate your production planning and shop floor. 's customer management, sales orders, inventory, purchasing, accounting, and financial reporting make real-time coordination across all your business verticals easier.

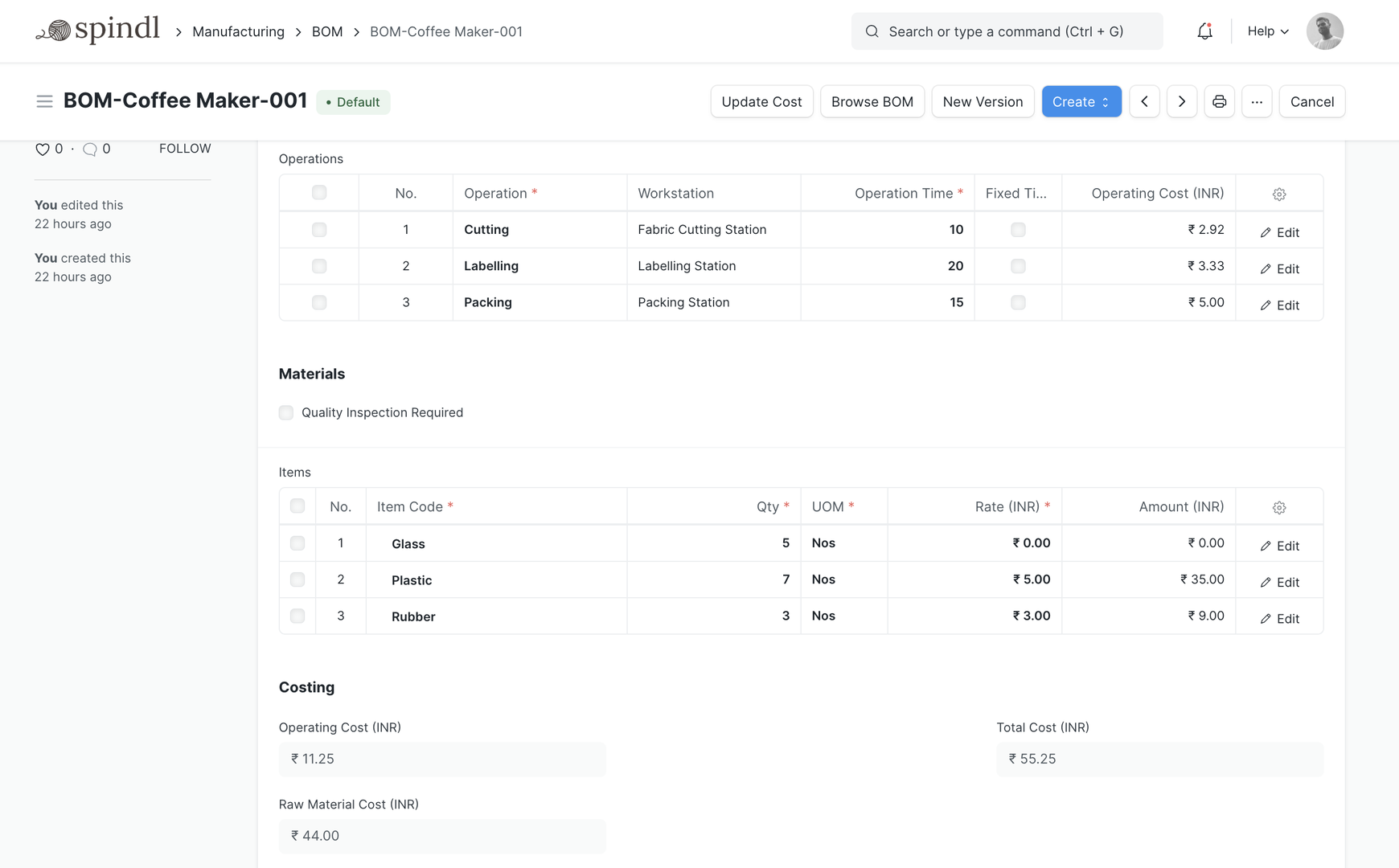

Bill of material (BOM)

A bill of material is at the heart of any cloud manufacturing software, and a well-defined BOM ensures robustness and accuracy. 's BOM is hierarchical, with the finished product at the top. It also includes product codes, part descriptions, quantities, costs and additional specifications.

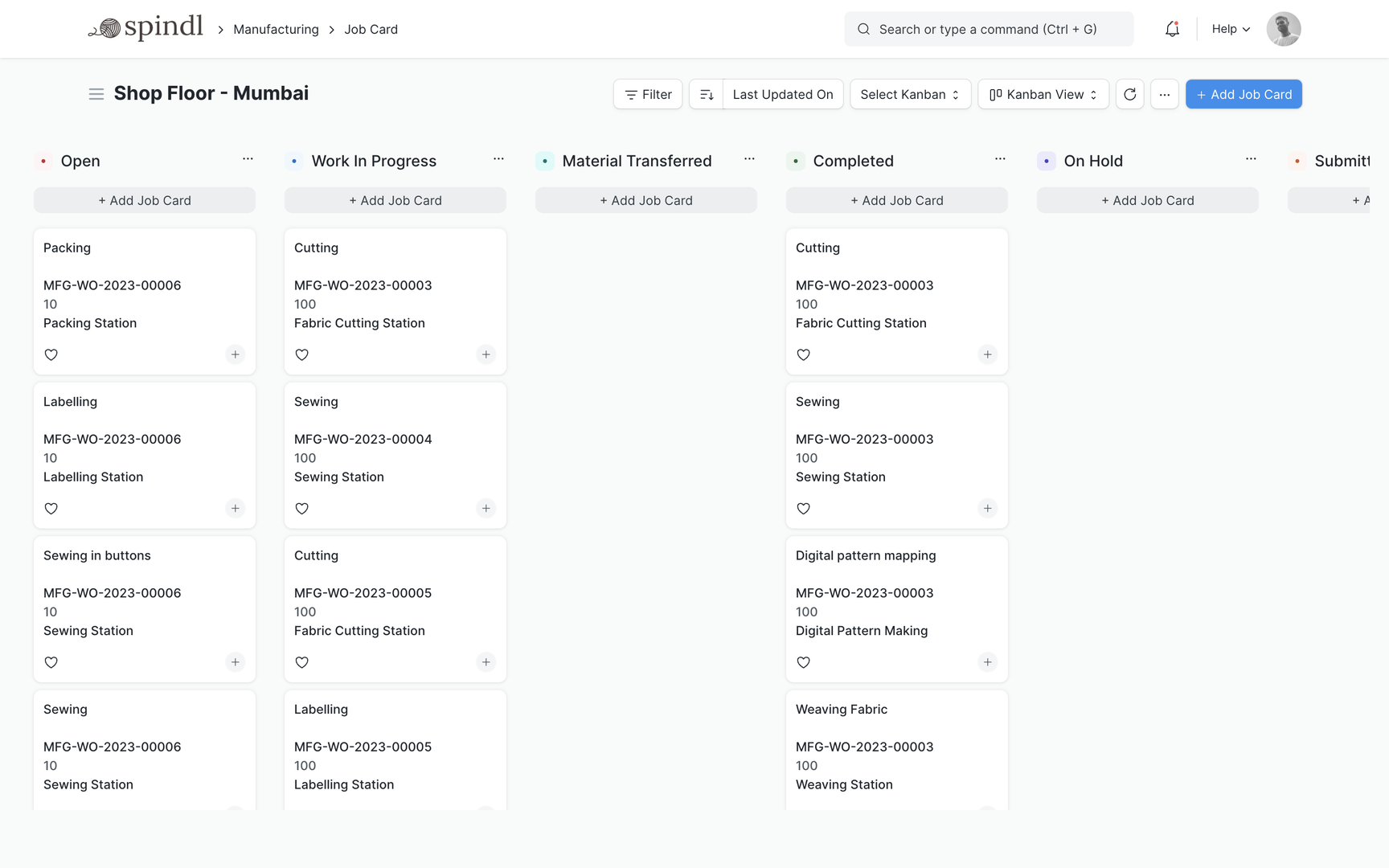

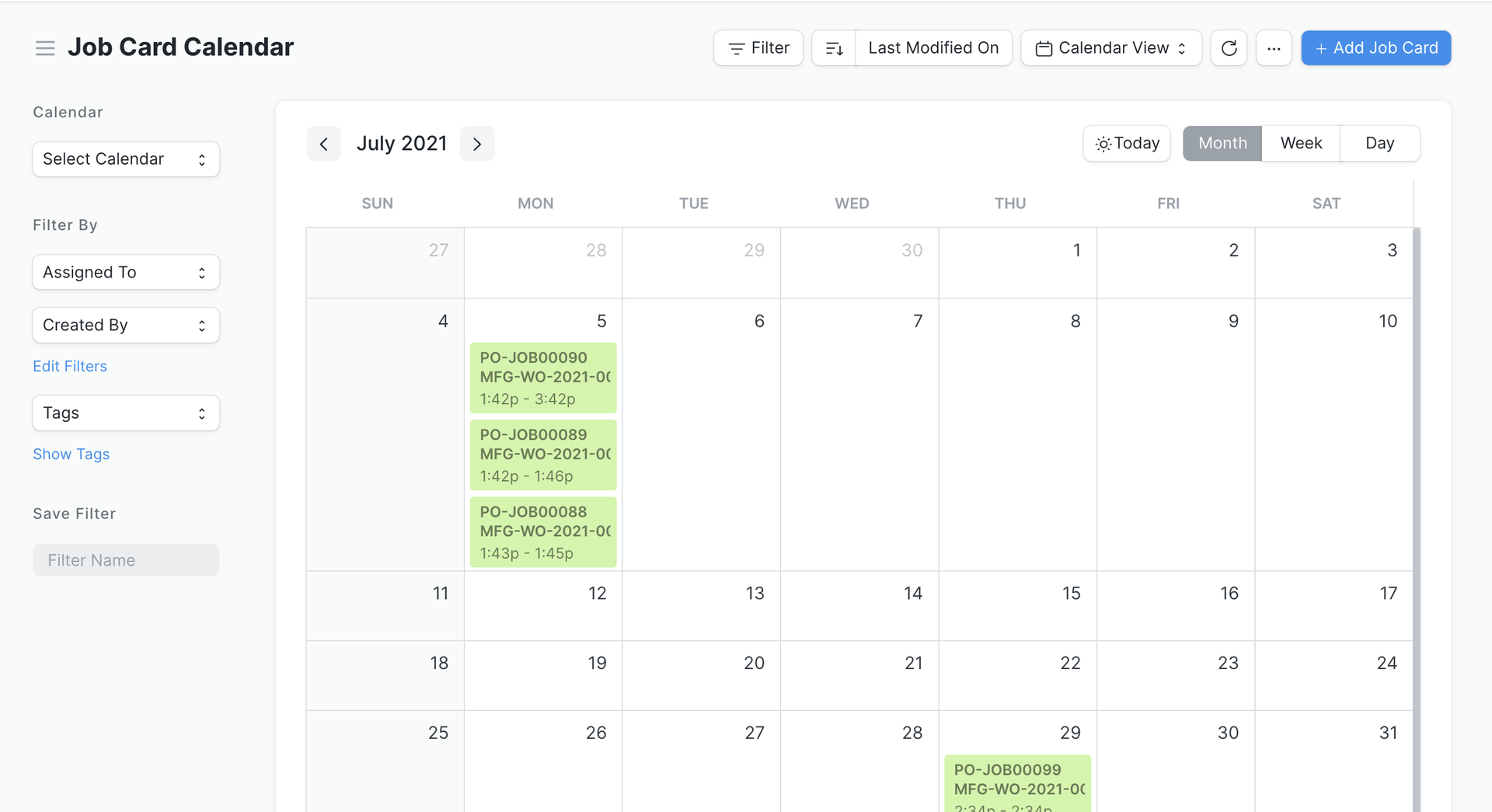

Shop floor management

With 's job cards, operations and workstations features, you can automatically capture daily activities on your shop floor. View real-time status of the job work being done to manufacture products, the location of every workstation, employee assignments, and each work order's current status and pending steps — all in one screen.

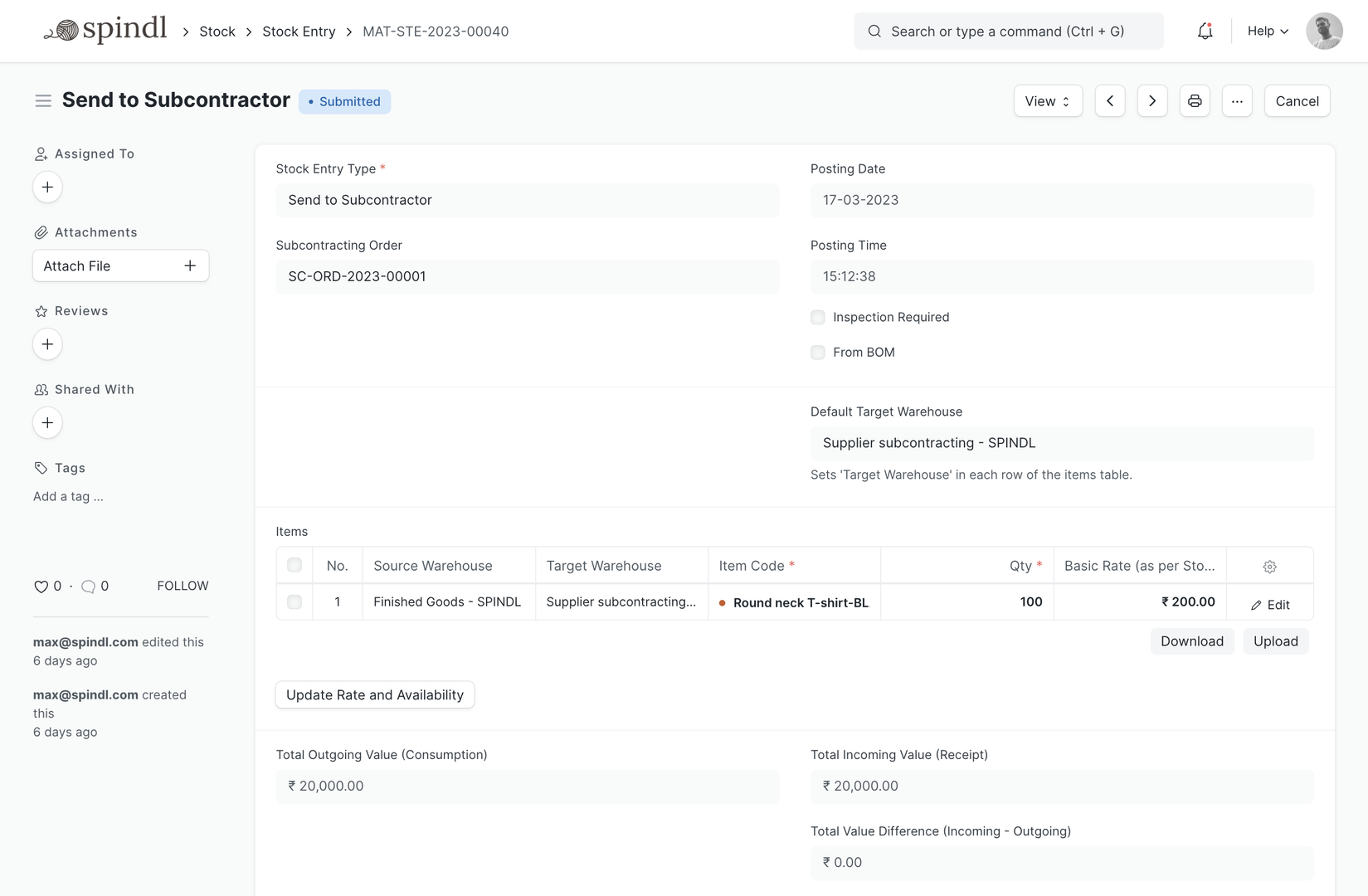

Subcontracting

Does your business involve outsourcing processes to a supplier? Check out the subcontracting feature in . It makes it easy to supply raw materials and track suppliers' labor and operations. Finished goods are valued based on the cost of raw materials and procured services.

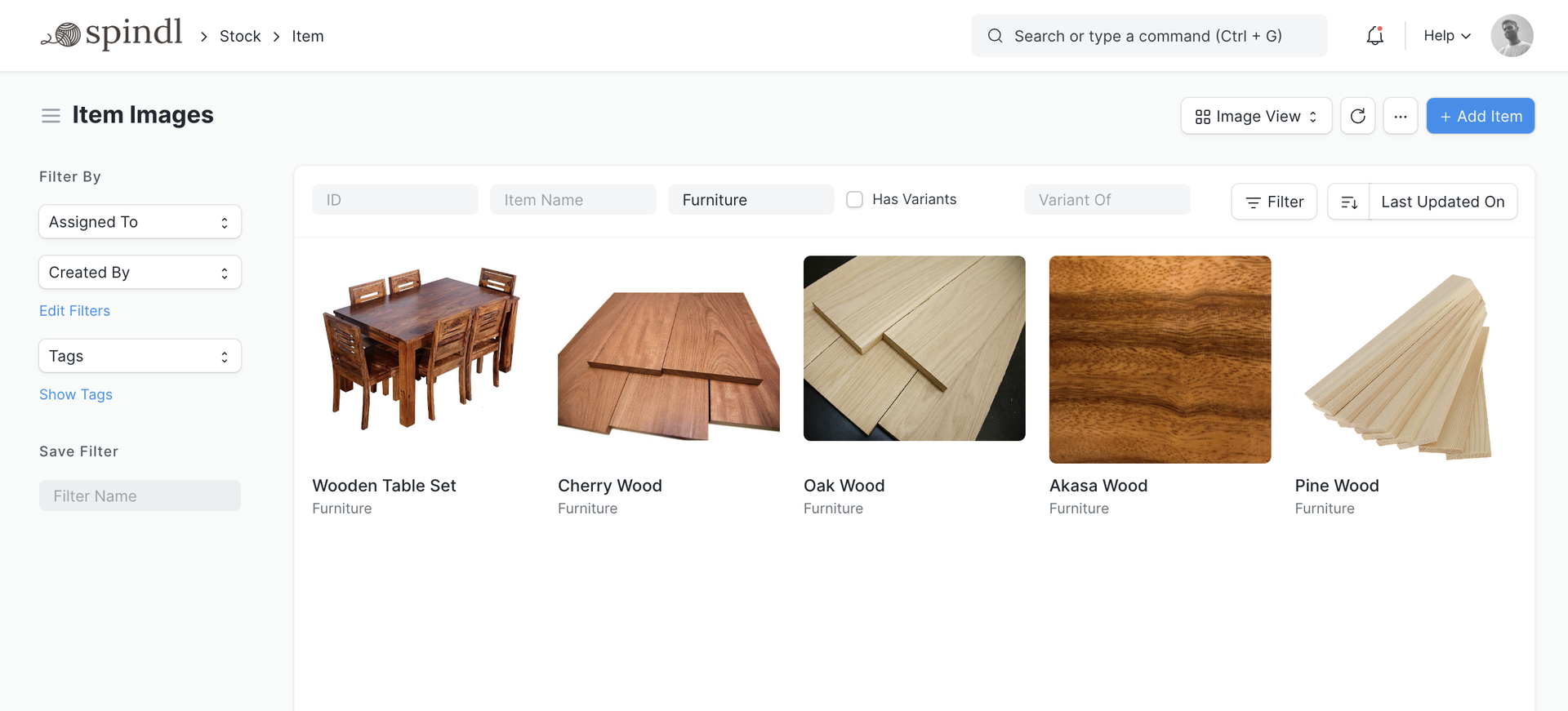

Item variants

Suppose you produce t-shirts in different sizes and colors. You'll need to track each type of t-shirt and its variants, known as item variants. In , the primary item is stored as an item template, and each of the variations is stored as an item variant. You can store any attribute, such as color or shape, for each item variant.

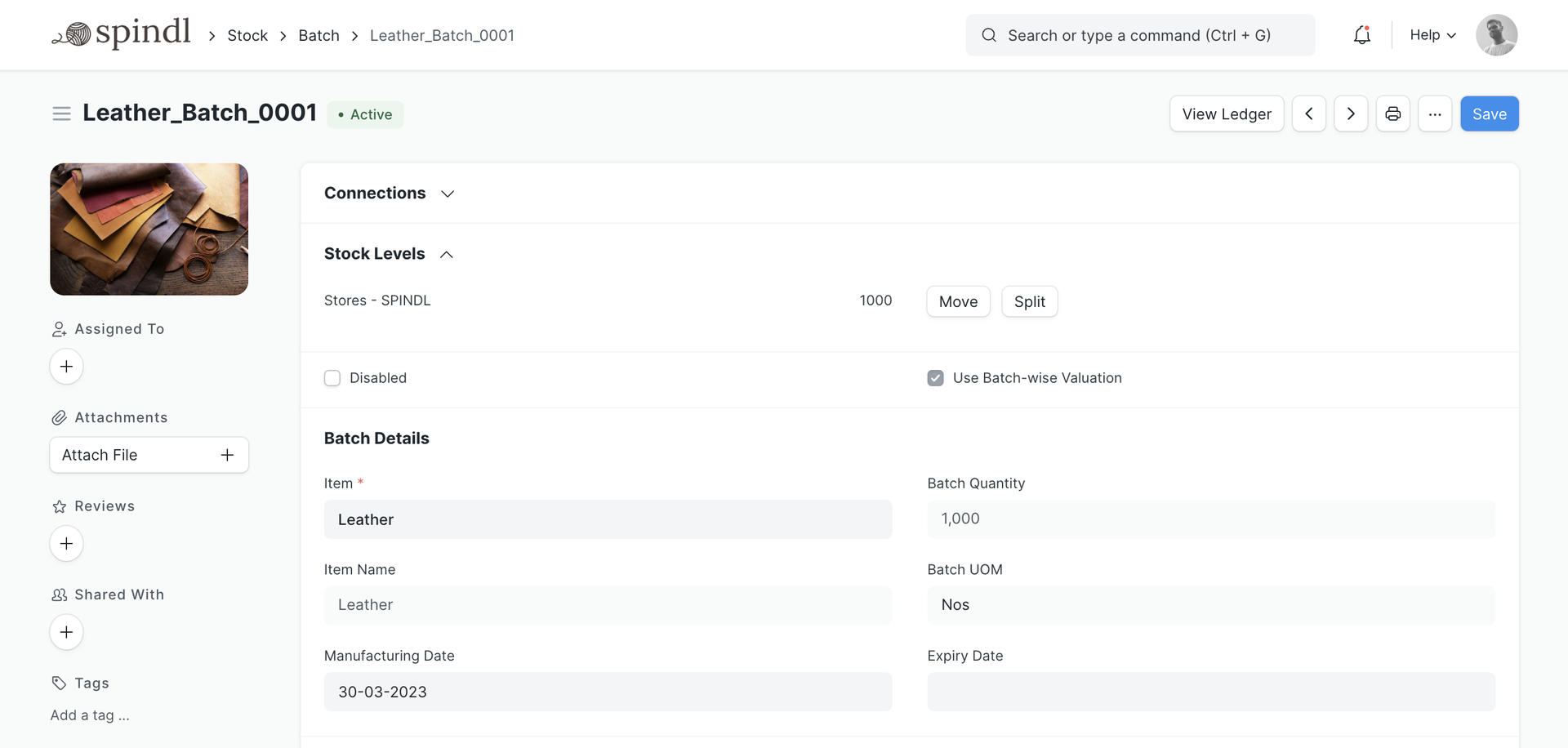

Batched inventory

With 's integrated inventory, managing batched items is simple. Its real-time view of product availability maintains each batch's manufacturing dates, expiration dates, and other details. You can even scan item barcodes with your device camera to quickly search through your stock and make data-driven decisions.

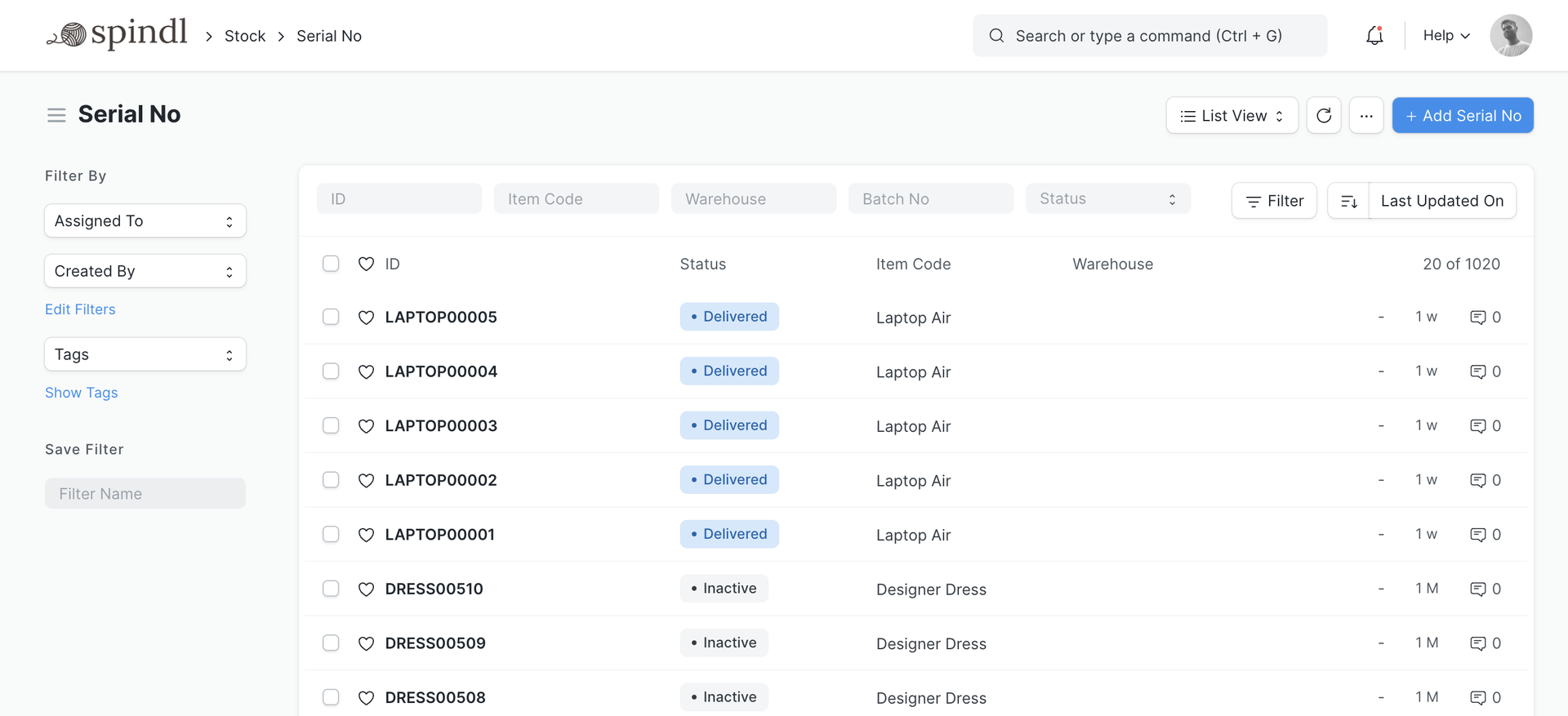

Serialized inventory

Use serial numbers to uniquely identify units. Set up naming series, and will automatically create serial numbers for new stock. You can even scan item barcodes via your device camera for easy search through all your stock.

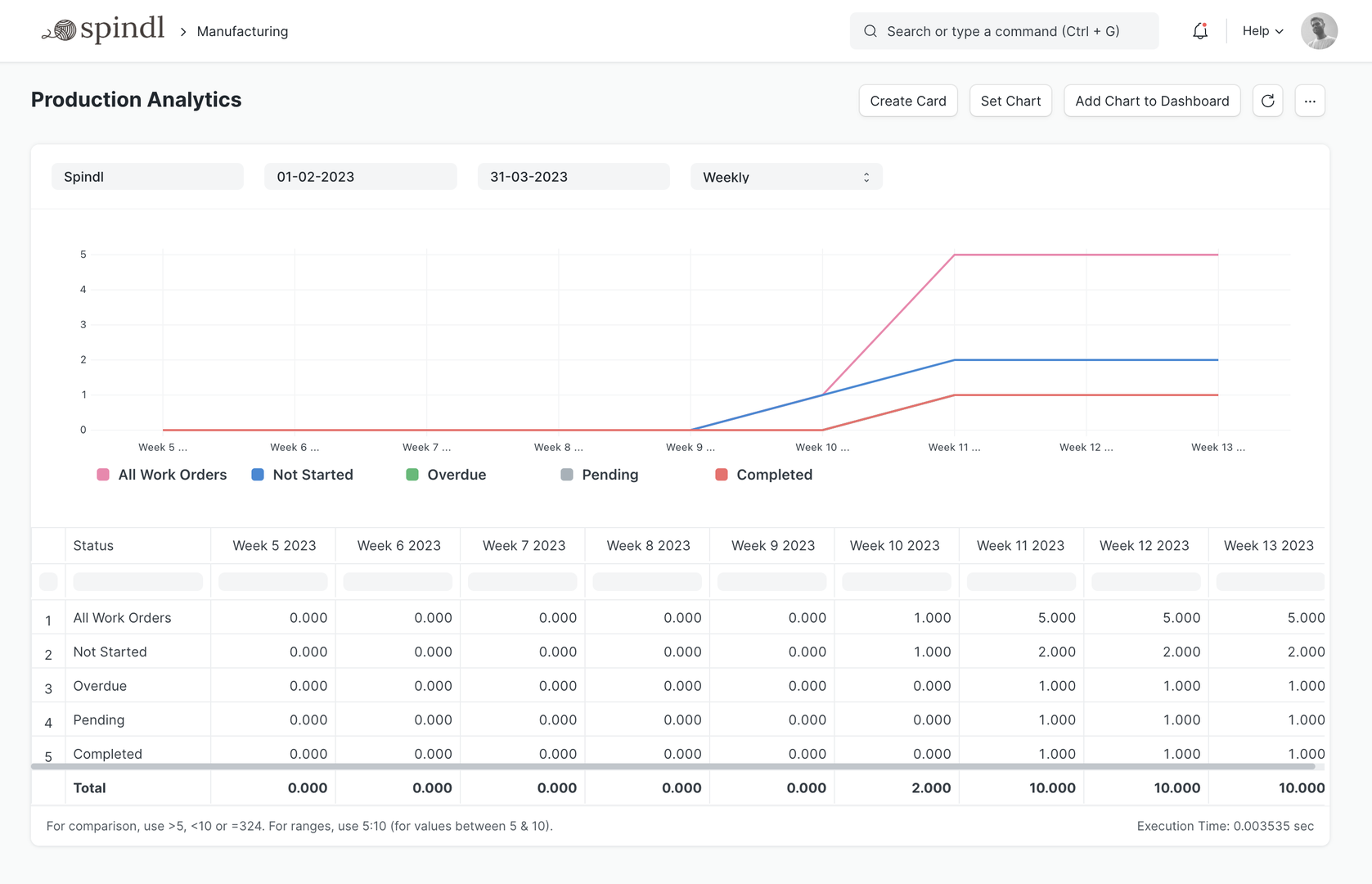

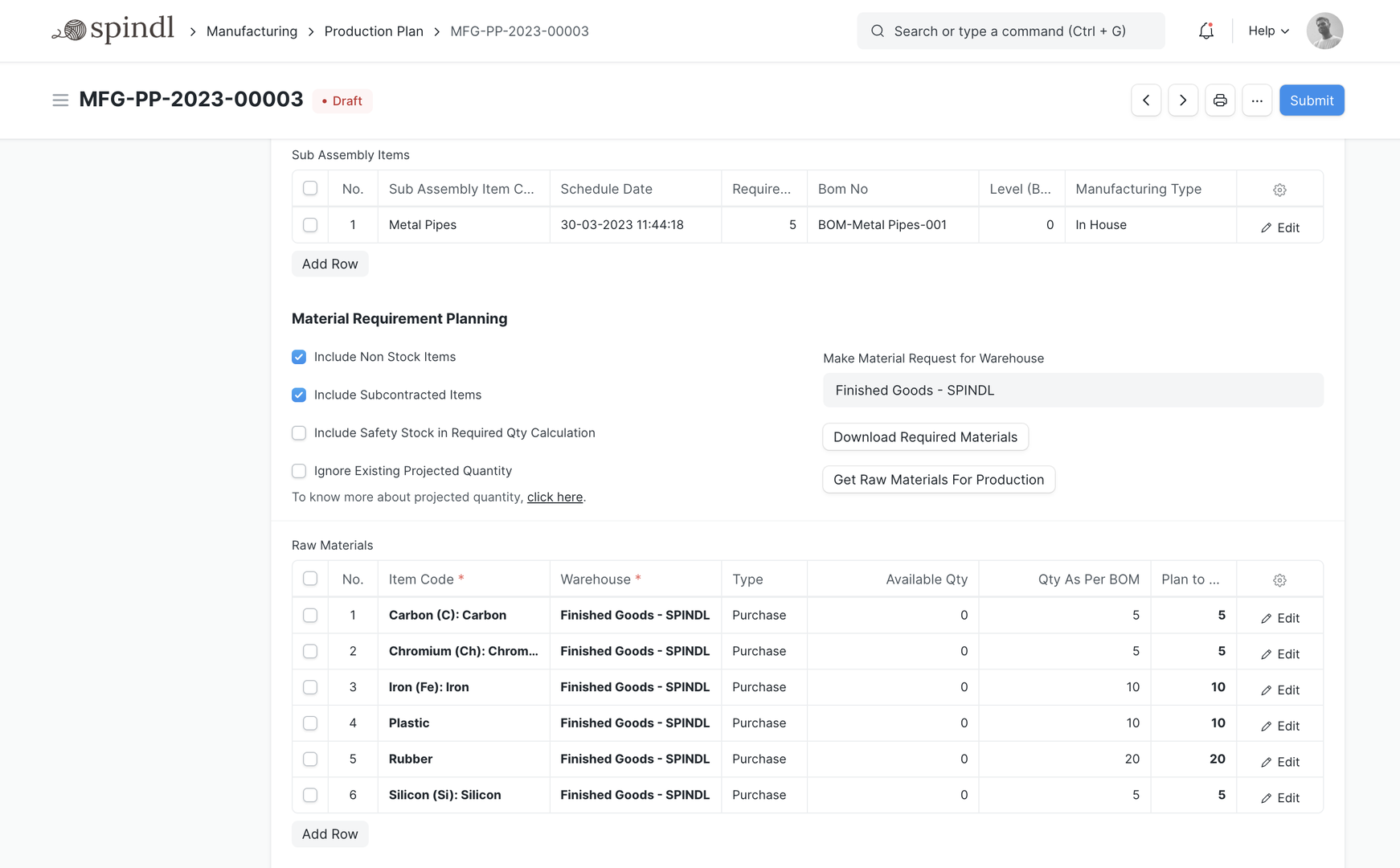

Material resource planning

Be it a work order against sales or material requests, will show every aspect of your MRP. Track material consumption of serialized or batched inventory to curb expenses and achieve zero wasted resources.

Capacity planning

Optimize your workstations based on the resources available for open production orders. Identify and eliminate bottlenecks at the shop-floor level by creating a capacity plan. You can also maintain and manage planning schedules for a predefined period of time (30 days, 45 days, etc).

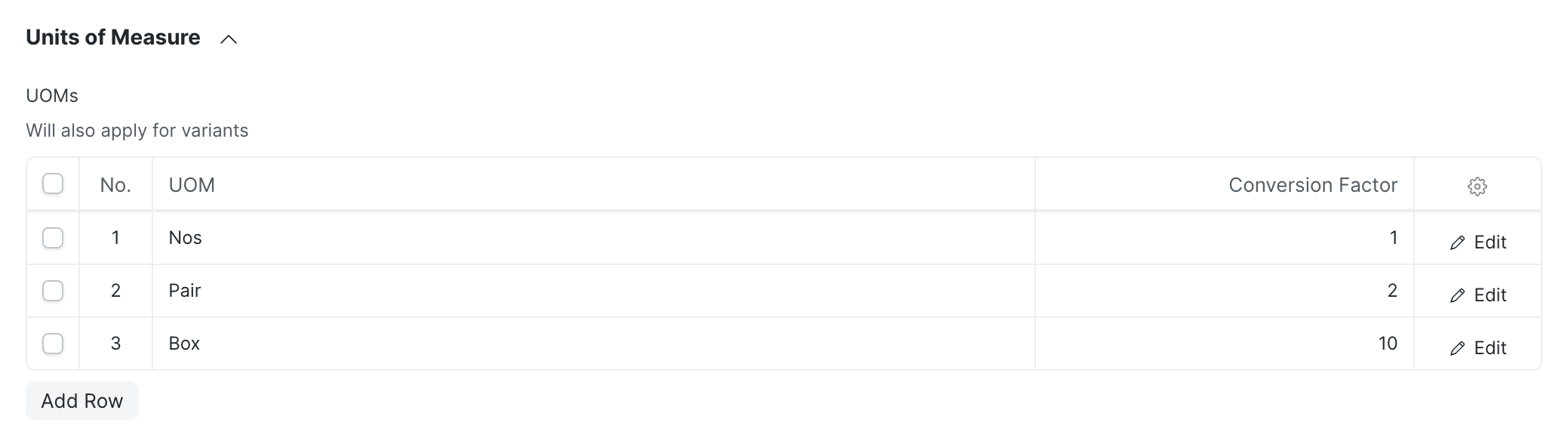

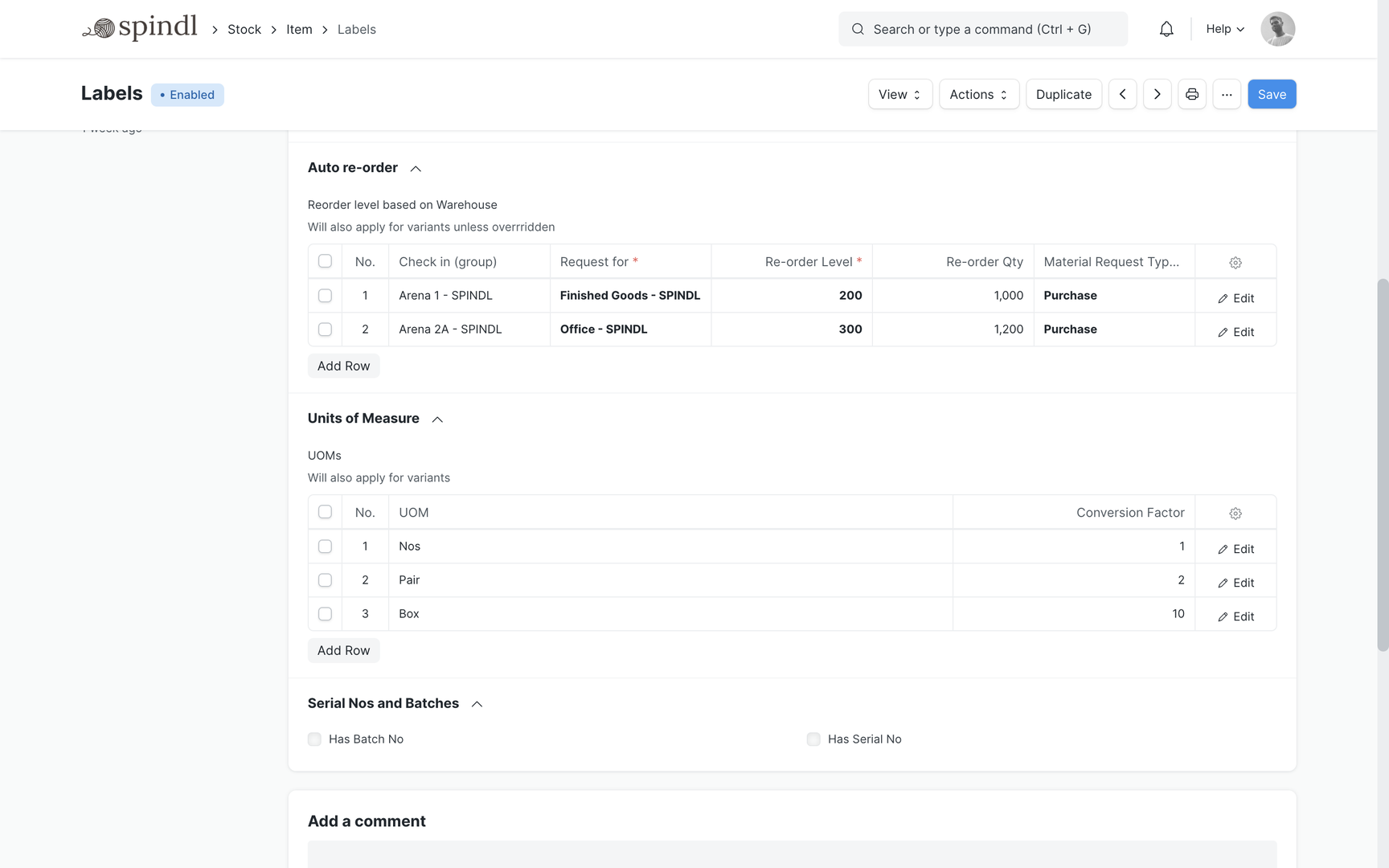

Multiple units of measure

Don't let systems stop you from measuring materials exactly the way you want! Keep track of different units of measurement for your inventory. Set up conversion factors in the Item master itself and facilitate smooth sales, purchase, and stock transactions. All conversions will be handled by the system.

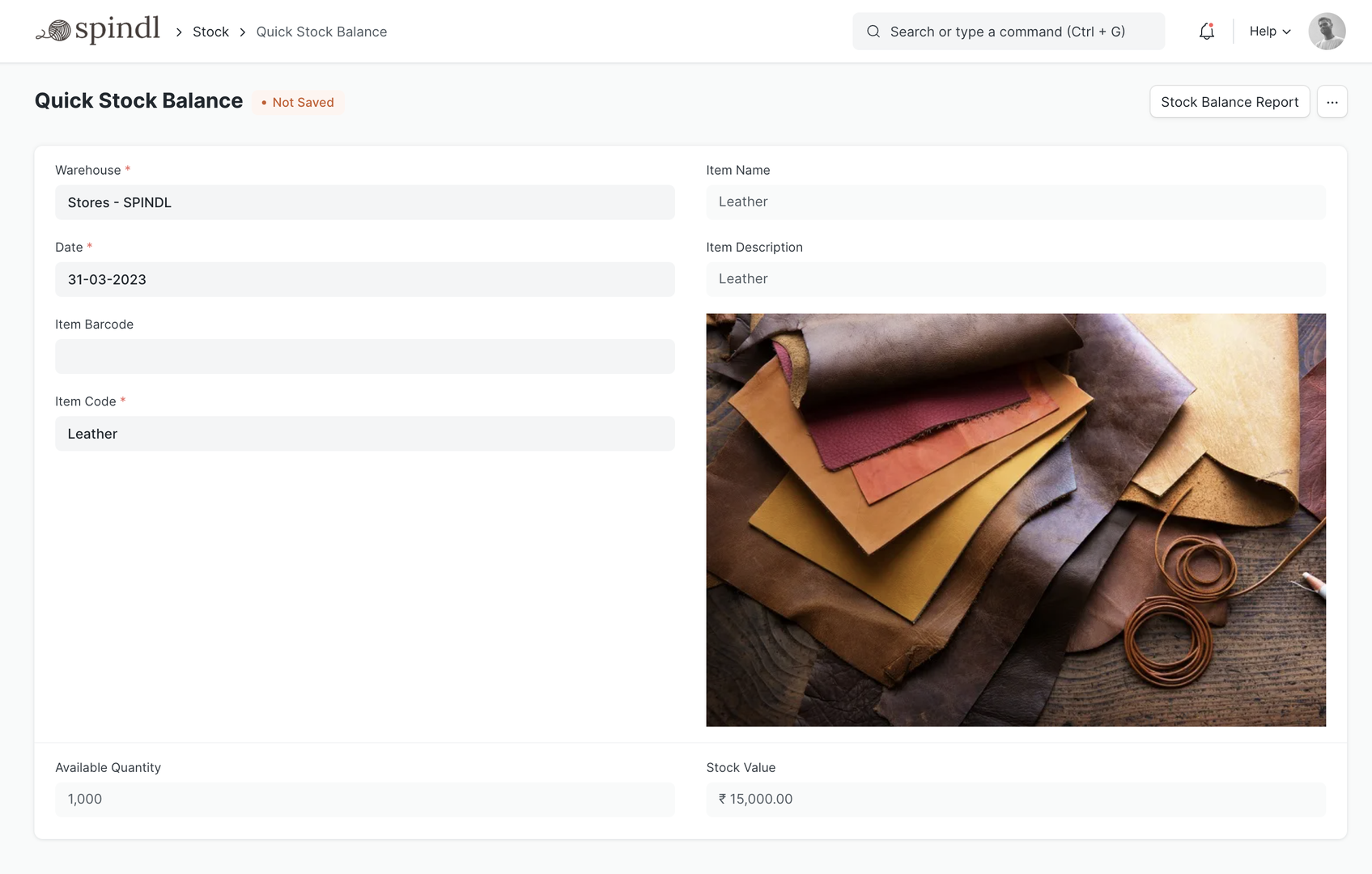

Quick stock balance

With the quick stock balance report, you can perform stock audits to verify stock at the warehouse, and check it against stock logged in the system. Simply scan a barcode with any device (no barcode scanner required!) and start counting.

Stock replenishment

To prevent stockouts, track an item's reorder level. When the stock level goes below the reorder level, will automatically create a material request. This helps you replenish inventory at exactly the right time and reduce chances of stock exhaustion.

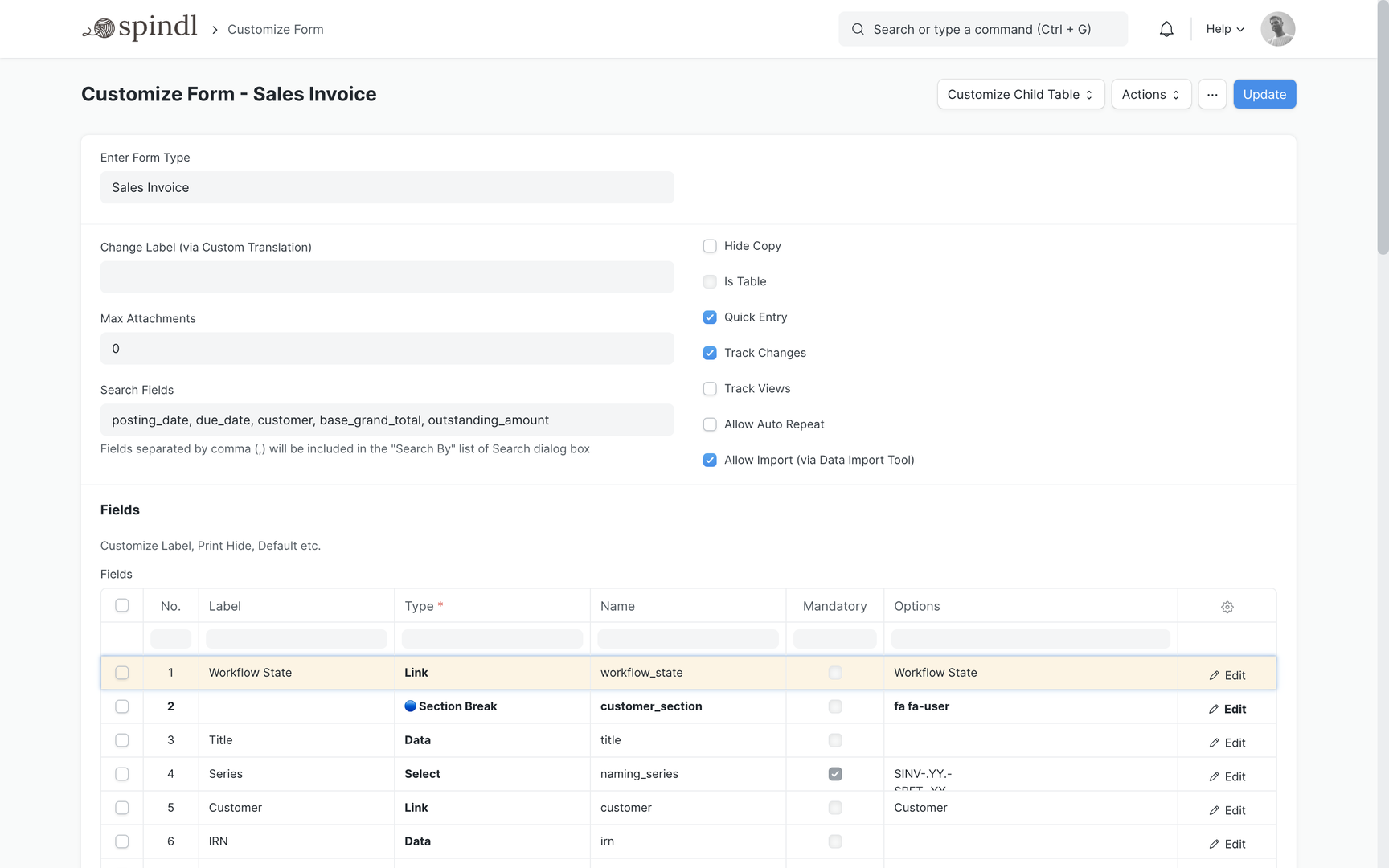

On-the-fly customizations

Create your own custom cloud manufacturing ERP software. Map your most important data by adding custom fields in your forms. Customize form behavior by auto-fetching values, hide fields based on user roles, and create custom print formats — all without a single line of code.